A few words about energy counting

As various energy sources are getting scarce and harder to extract their price will inevitably rise. This will cause the price of manufactured goods to rise as well and thus making it harder for any company to stay in business. The energy counting system developed by VERTESZ Electronics is a viable option that provides cost-efficient operation. The system is suitable for wide variety of conditions, including electricity, water, gas, steam or any other source of energy. At the most essential level, the system is constantly monitoring actual energy consumption, and based on that it is able to reduce waste. If the company is aware of its consumption schedule and is able to reduce its consumption, it is a good starting point to renegotiate its contract with the energy provider. This can help the company to compete with better prices and achieve a better position on the market. Energy counting systems can be used not only in the manufacture industry but by public institutions, commercial centres, service providers, in short, in any establishment that is conscious of reducing its expenses.

VMAX maxlimiter and schedule-keeper

This instrument may prove to be indispensable for consumers using a fixed consumption schedule. The scheduler algorithm runs once every cycle, ensuring that the energy (electricity, gas, water, etc.) consumption of all the consumers it is monitoring stays within the domain of EMIN…EMAX in every given cycle (of 15 or 60 minutes) that is, neither over- or underconsumption occurs.

The device makes an estimate of the total energy consumption for the cycle based on the monitored values of consumption. Depending on whether this estimate is positive or negative, the VMAX decides to turn consumers on or off in order to conform to the schedule. The priority sequence of consumers can be set beforehand.

Every measurement cycle begins with an adjustable length time out, since the initial estimate of the first few minutes can be inaccurate. The duration of the time out can be set between 1 and 15 minutes (in practice, 3-4 minutes are sufficient), after which the maxlimiting algorithm continues with adjustable cycles (1-60 seconds).

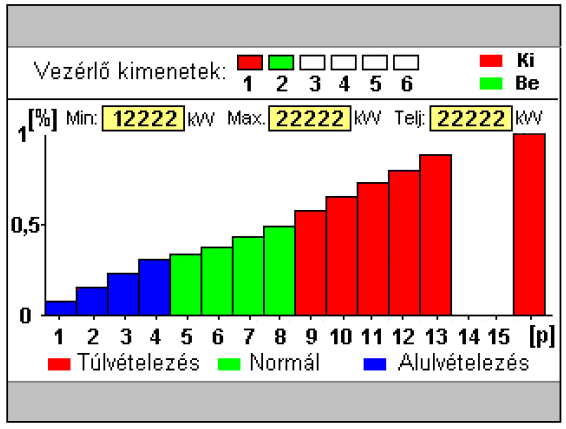

The built in colour LCD shows the consumption of the last 15 minutes on a bar graph. Every bar represents 1 minute, the colour green means normal consumption, red is overconsumption and blue is underconsumption. Control outputs that are on are indicated by a green light, the ones turned off are red.

Depending on the settings, the instrument registers consumption data and it can send detailed information on the actual, by the minute, quarter hourly, daily or monthly consumption through LAN to a PC for processing. It can also provide continuous readouts of current performances and of the state of binary in and outputs

Inputs:

Inputs are available for 1 current transformer, 1 for 15 minutes synchronisation, and 32 for pulses from various meters. Maxlimiting can be applied to any given input.

Outputs:

No restriction on the number of control outputs.

VMAX scans the following data when deciding about a consumer:

- Current state (on or off)

- Available power

- Priority level

- Reclosing option

- Delayed switching

Power supply:

Ut: 230V AC

Internal UPS.

The UPS and the internal memory guarantees that no data lost even in the case of communication breakdowns.

Internal UPS (enough for 12 hours). ■ ebouncing inputs that are active or passive depending on whether they are connected or not. ■ Data can be read continuously and are committed to memory every minute. ■ 400x500x200 mm steel cabinet ■ Noise protection for all devices

VEGA 2000 complex energy counting system

Steps for proper energy counting: measurement – data collection – evaluation – decision

Principles

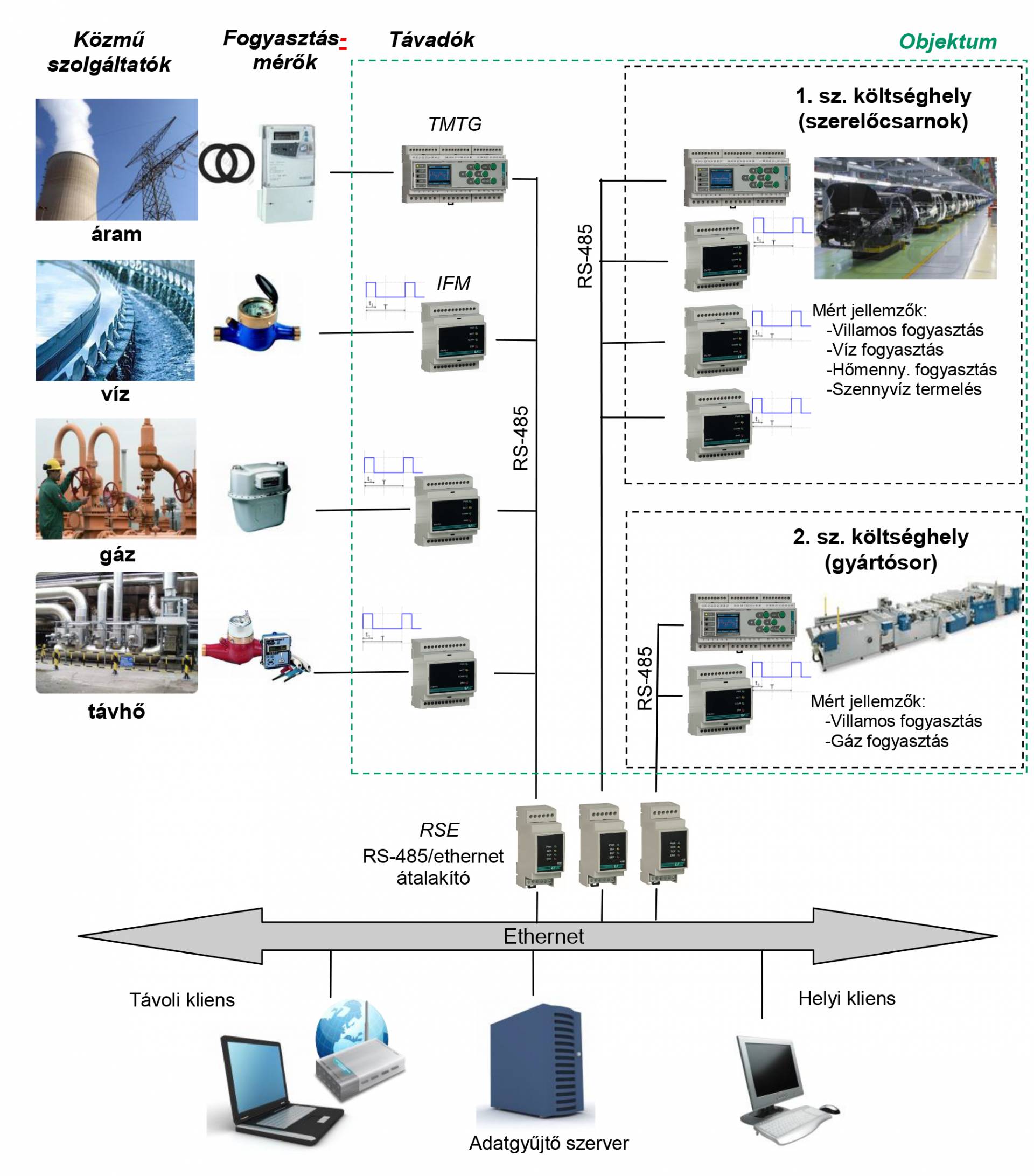

Energy arrives to the building at designated supply points. It is compulsory to have certified energy meters at these points. There are “n” number of branches inside the building that are used by internal consumers (cost centres). Further measurement locations may or may not have to have certified energy meters, depending on the internal regulations. Using transmitters is preferred as they make processing easier. Each cost centre may be divided into further sub-cost centres, for example a business premise, each of those can have its energy consumption registered separately.

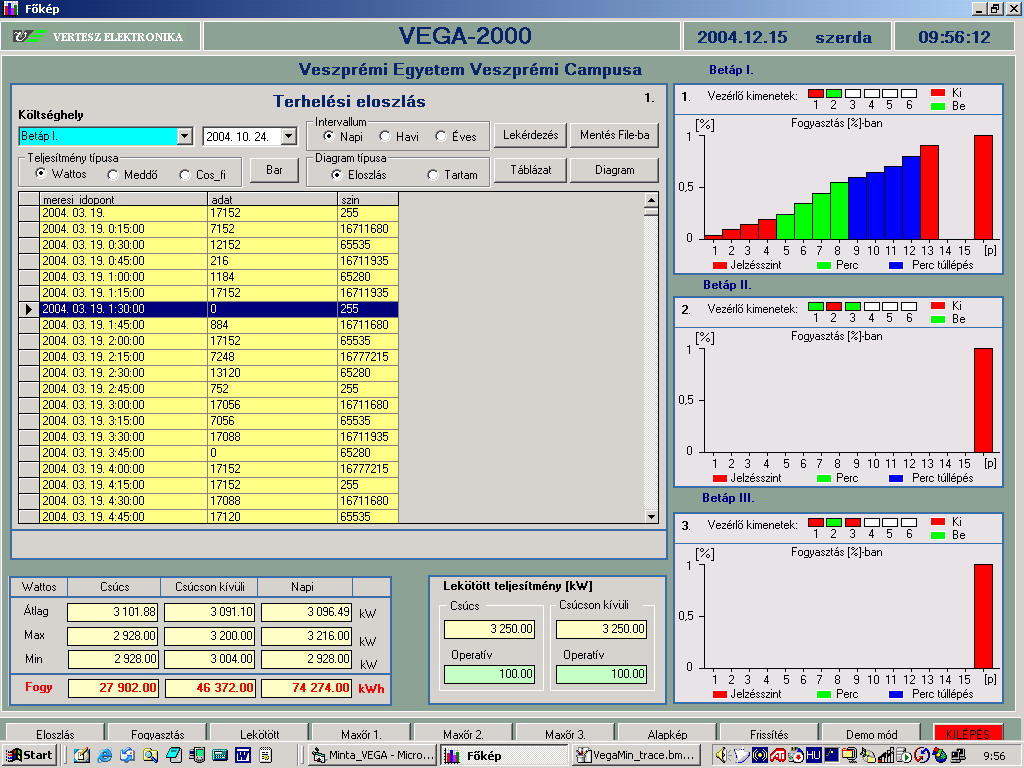

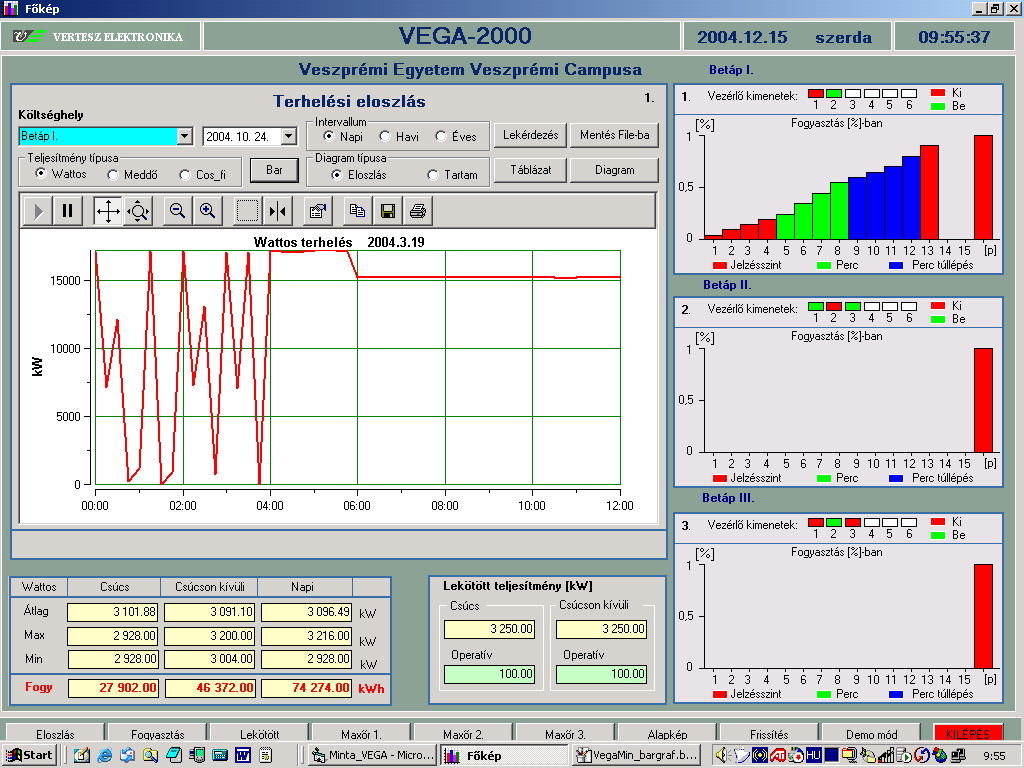

The energy meters are connected to a communication network that is fed into a computer processing the data. This computer is running the VEGA software, which is designed to fulfil a number of tasks, such as collecting, registering and evaluating data, grouping it according to consumers, price calculation, cost accounting, schedule control, etc.

Measurments

Energy counting starts with measurement. One has to determine who consumes, when, how much of which source of energy. Only when these data are at hand can a business decision be made

We would recommend using TMGT type energy counters manufactured by our company. These are capable of analogue and pulse-based measurements and can be synchronised to the main meter. Their measurements are highly precise (0,2 % margin of error) due to noise protection and a special mathematical process. Devices of other manufacturers can also be connected if equipped with the appropriate communication outputs. It is crucially important to use a transmitter that it as accurate enough as there cannot be a discrepancy between the readouts of the certified supply point and the sum of the other submeters. When using pulses, the user have to synchronise the device to the main meter and other measurement devices.

Data acquisition

Data collection is done by a computer running the VEGA software that issues a query to the measurement instruments regularly (time period is adjustable between 1-60 minutes). Clock synchronisation of the data collector and measurement points is essential to ensure accurate registration. Means of communication is not predefined; the cheapest and most wide-spread solution is using an Ethernet network, because most companies already have a LAN set up for connecting computers.

It is very important for the measurement instruments to have internal memory, as it can prevent losing collected the data even when the communication network is malfunctioning. If they lack internal memory, actual energy consumption will differ from the one measured. Every TMTG manufactured by VERTESZ comply with this requirement, as those can store data for 40 days.

In the event of a communication failure, data can be input to the software manually, thus ensuring continuous cost accounting.

Evaluation

Close scrutiny of the sub-cost centres will reveal how much energy is used at each location, or where losses originate from.

The software can create reports and analyse trends of a given period of time, which in turn can provide experts with valuable data to determine what steps to take in order to make the given location or technology more cost-effective.

Decision

After evaluation, it is possible to determine the energy cost of each service and industrial segment that can serve as the foundation for technical and economic decisions. For example, decision-makers can now asses energy cost of 1 product.

(a “n” number of products can be manufactured in 1 hour, using “x” amount of electricity, “y” m3gas, “z” m3 water, or “v” m3 of waste water was produced, or “w” kVAr reactive power was used.)

After the decisions are made, manual or automated changes can be implemented using FKM modules or a TELPAM 2000 in larger systems.

Based on prior experiences, the investment turnover period of installing the energy counter system is 0,5-2 years

Additional functions of the VEGA system

- Besides calculating actual power consumption, it is also possible to count reactive energy.

- Recordkeeping of measurement instruments, thus enabling easy inventorising, indicating certification dates, etc.

- Assessing trends that can help deeper analysis.

- Displaying current, by the minute, hourly, monthly data of each measurement location

- Handling adjustable user authorisation.

- Automatically calculating the consumption of sub-cost centres, and does cost accounting based on company information stored in the program.

- Periodic archiving

- Logging unusual events and violation of limits.

- Can provide data for the accounting programs.

- Diagnostic tools are available for uncovering errors.

- Accessible via the Internet.

References

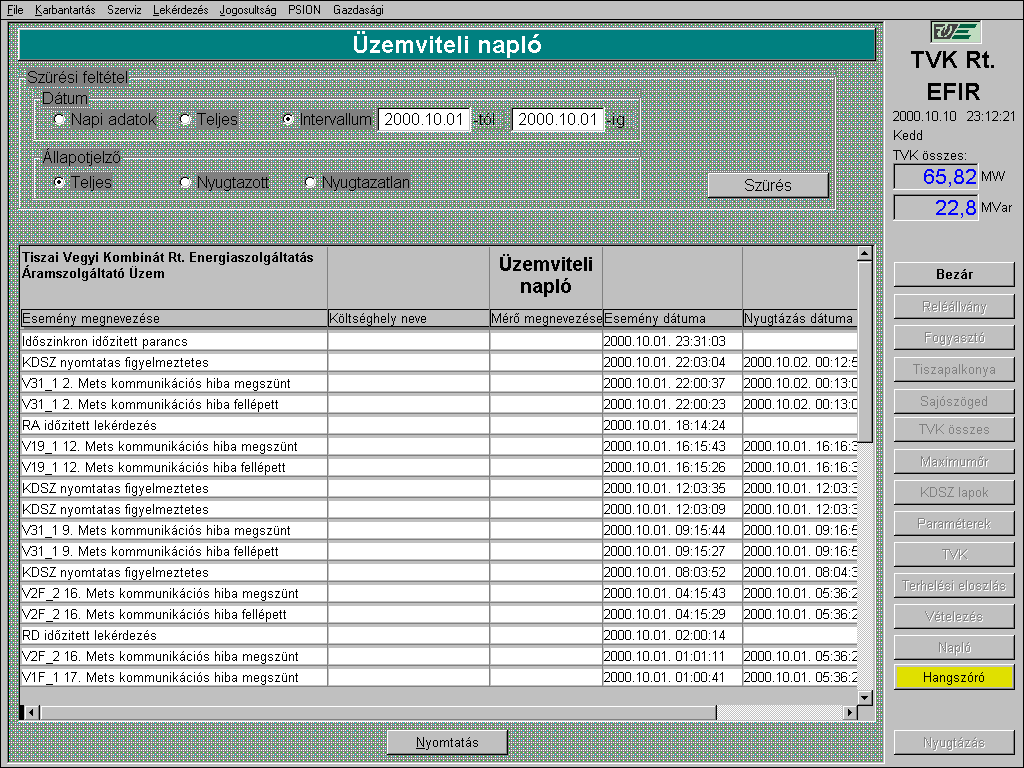

TVK Rt. energy counting

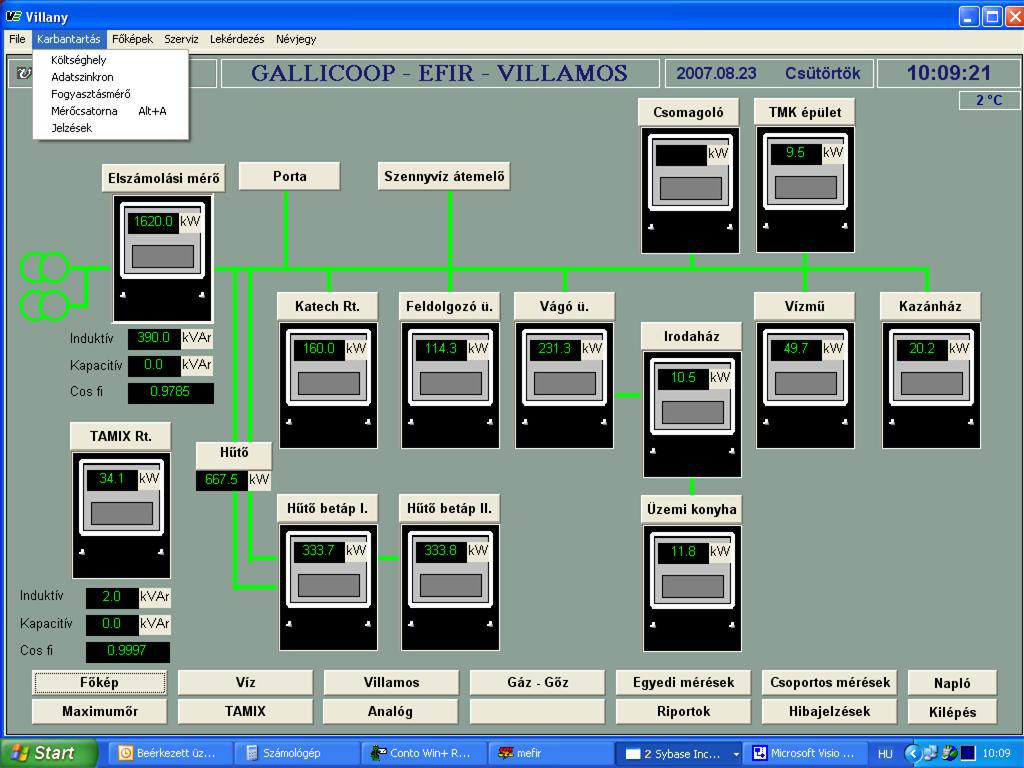

Gallicoop Rt. (electricity, gas, water)

IBM electricity counting system

Várdavulkán Kft. (foundry) electric maxlimiting

Péti Nyitrogénművek Rt. electricity counting system

Kőbányai Sörgyár electricity counting system

Dunai Kőolajipari Vállalat energy counting

Chinoin Rt. Veresegyháza energy management

Aréna plaza complete energy consumption counting system

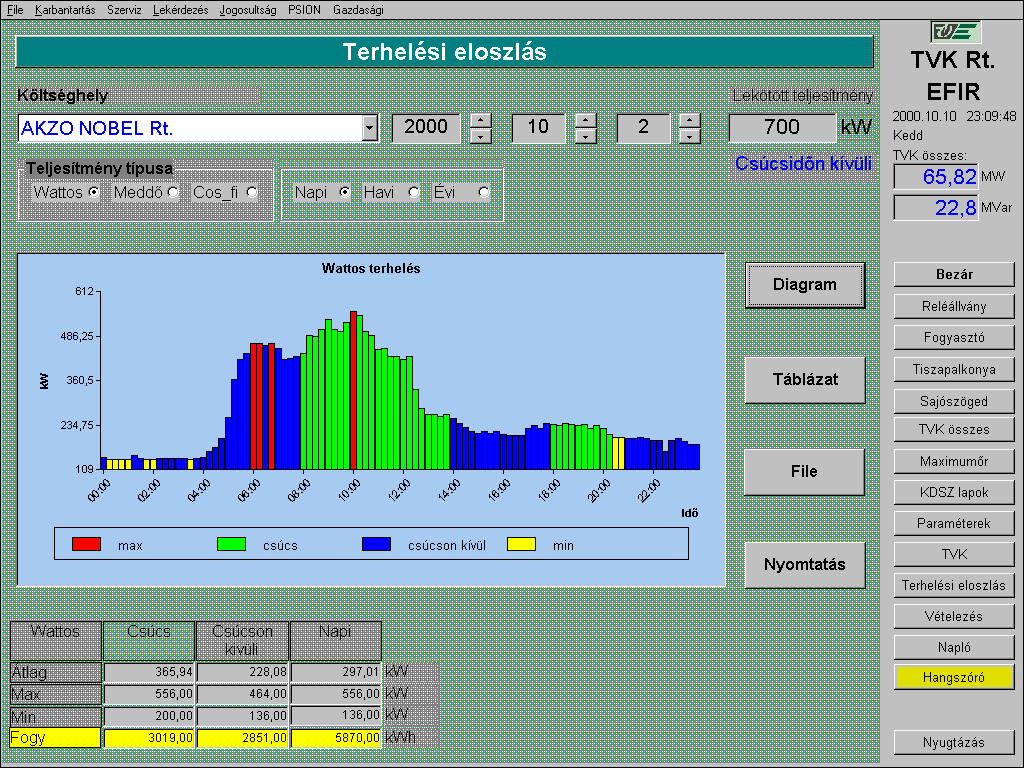

Example of displaying energy load distribution in a spreadshet

Example of displaying energy load distribution

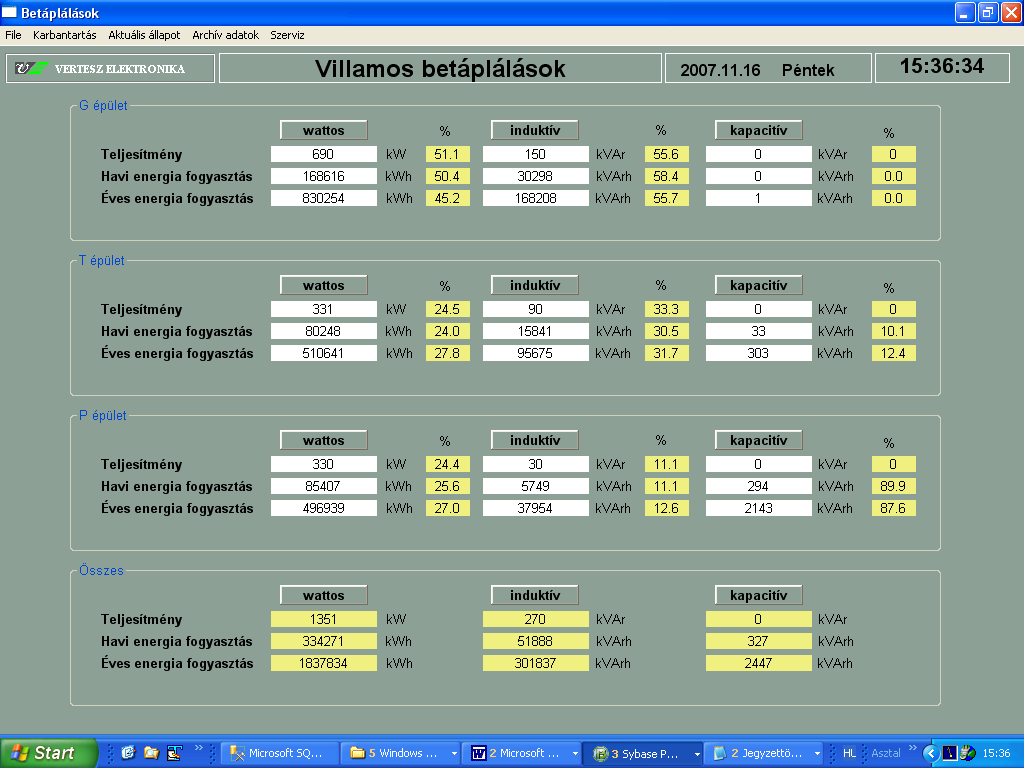

Example of a main screen in VEGA

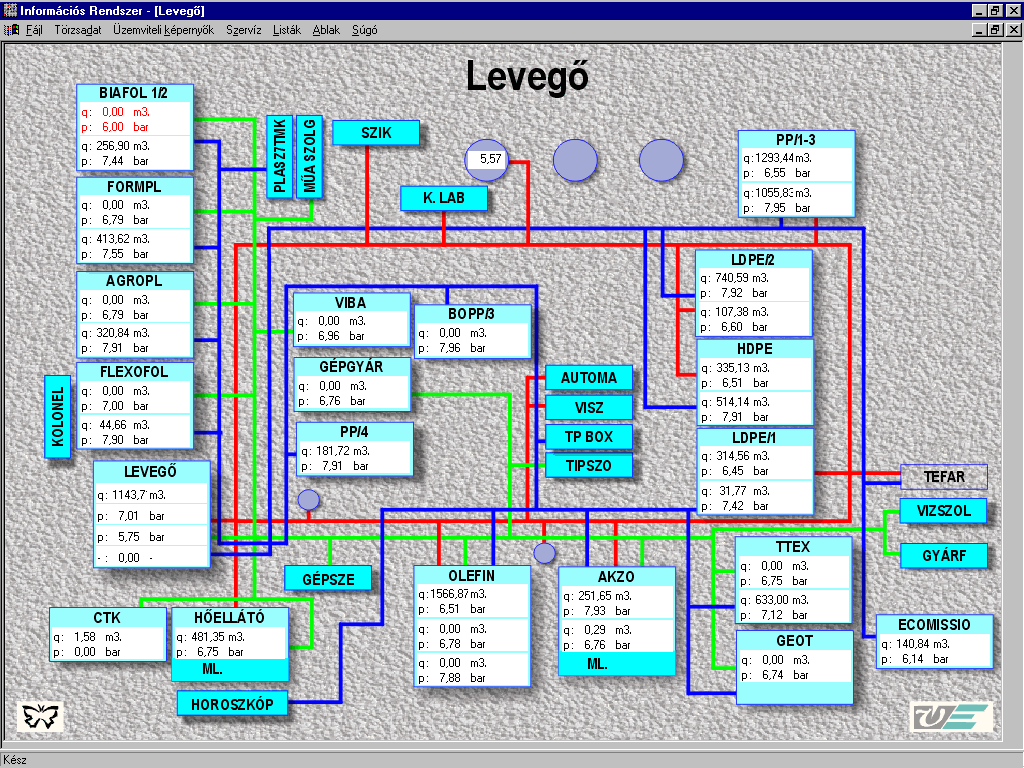

Example of a compressed air system in VEGA

Example of a log in VEGA

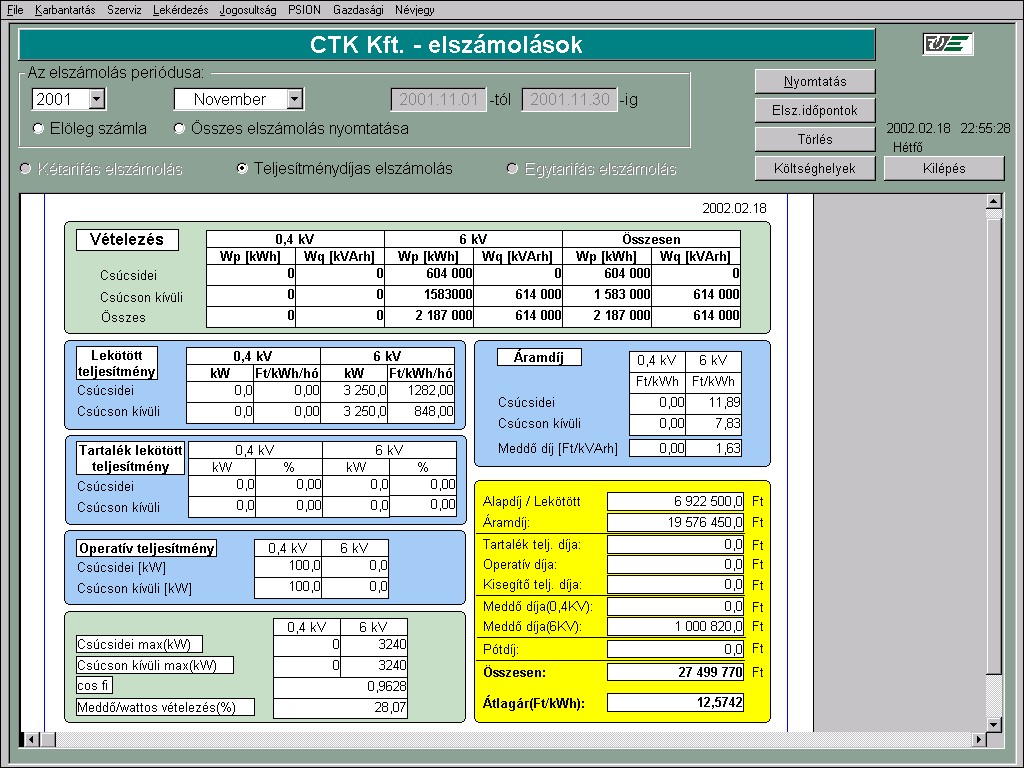

Example of an energy invoice calculation in VEA

Example of a daily load curve in VEGA

Example of an actual load display in VEGA

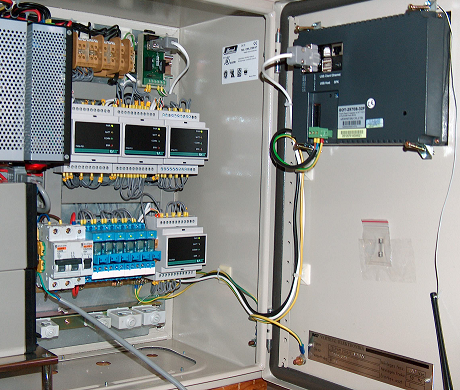

Devices used in the system

TMTG-3E – energy counter transmitter

[not only for electricity]

IFM – pulse receiver input module

RSE – RS485/Ethernet transformer